AUTOMOTIVE ENGINEERING

16 subscribers

About AUTOMOTIVE ENGINEERING

( Mechanical engineering - engine technology )

Similar Channels

Swipe to see more

Posts

📌 6 Essential Car Fluids: What They Do & When to Replace Them: 1. Engine Oil: Lubricates and cools engine components. • Replacement: Every 5,000 to 10,000 miles. 2. Transmission Fluid: Lubricates and cools the transmission. • Replacement: Automatic: 30,000-60,000 miles | Manual: 30,000-50,000 miles. 3. Differential Fluid: Reduces friction in the differential gears. • Replacement: 30,000-60,000 miles. 4. Brake Fluid: Transfers force for braking. • Replacement: Every 2-3 years. 5. Engine Coolant: Regulates engine temperature. • Replacement: 30,000-100,000 miles. 6. Windshield Washer Fluid: Cleans windshield for visibility. • Replacement: Refill as needed. #carfluids #automaintenance #carlife #enginesafety #brakecare #transmission

Understanding the various types of suspension systems is crucial for selecting a vehicle that aligns with your driving preferences and requirements. Here’s a concise overview: 1. Independent Suspension: • Concept: Each wheel moves independently, enhancing ride comfort and handling. • Examples: MacPherson Strut, Double Wishbone. 2. MacPherson Strut: • Concept: Integrates the coil spring and shock absorber into a single unit. • Characteristics: Compact, cost-effective, and commonly used in front suspensions. 3. Double Wishbone: • Concept: Utilizes two control arms (wishbones) to position each wheel. • Characteristics: Offers superior handling and design flexibility, often found in performance vehicles. 4. Multi-link Suspension: • Concept: Employs multiple links to control wheel movement. • Characteristics: Provides precise control, allowing for fine-tuning of ride and handling, typically used in rear suspensions of high-performance cars. 5. Trailing Arm Suspension: • Concept: Features a pivoting arm that connects the wheel to the vehicle’s frame. • Characteristics: Simple and cost-effective, commonly used in rear suspensions of front-wheel-drive cars. 6. Non-Independent (Solid Axle): • Concept: Wheels are connected by a solid axle, so movement of one wheel affects the other. • Characteristics: Durable and suitable for heavy-duty applications, but can impact ride quality. 7. Solid Axle with Coil Spring: • Concept: Combines a solid axle with coil springs for cushioning. • Characteristics: Robust and capable of handling heavy loads, commonly found in trucks and SUVs. 8. Solid Leaf Spring Suspension: • Concept: Uses stacked metal strips (leaf springs) to support the vehicle’s weight. • Characteristics: Extremely durable, often used in trucks and heavy-duty vehicles. 9. Air Suspension: • Concept: Employs air-filled bags instead of traditional springs. • Characteristics: Allows for adjustable ride height and provides a smooth ride, typically found in luxury vehicles. Selecting the appropriate suspension system depends on your specific needs, such as desired ride comfort, handling performance, and vehicle usage. #Automotive #MechanicLife #Cars #CarParts #Suspension #CarEngineering #VehicleMaintenance Mechanics Reels

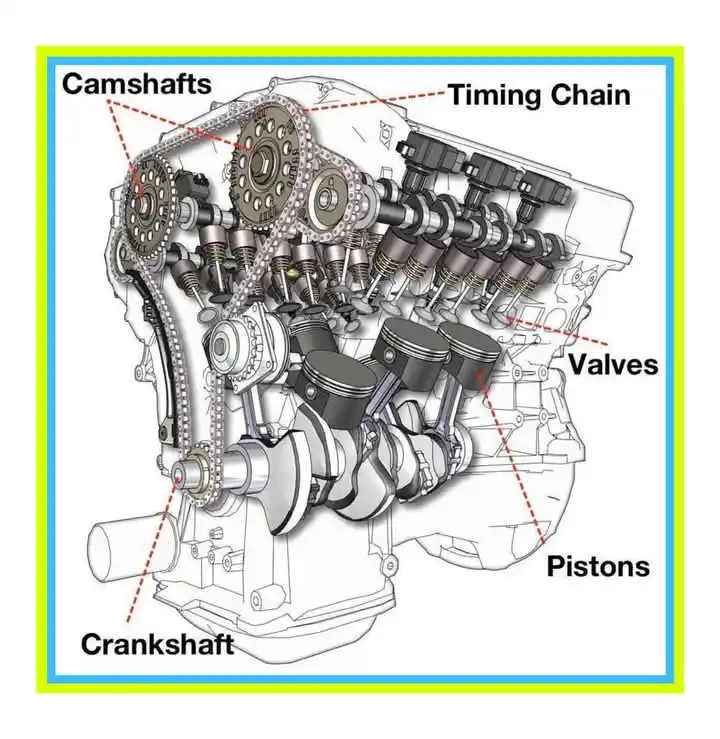

📌📌Key Engine Components📌📌 1. Camshaft Controls the opening and closing of intake and exhaust valves, ensuring proper air-fuel intake and exhaust expulsion. 2. Crankshaft Converts the linear motion of the pistons into rotational motion to drive the vehicle. It requires high durability for long service life. 3. Valves Regulate the flow of the air-fuel mixture into the engine and the exhaust gases out. There are two main types: intake and exhaust valves. 4. Timing Chain Synchronizes engine parts to ensure the proper sequence of the intake, compression, combustion, and exhaust phases. 5. Pistons Move inside the cylinder to convert heat energy into mechanical work, essential for powering the engine. #EngineComponents #AutoMechanics #CarMaintenance #EngineBasics #CarCare #VehicleTech Mechanics Reels

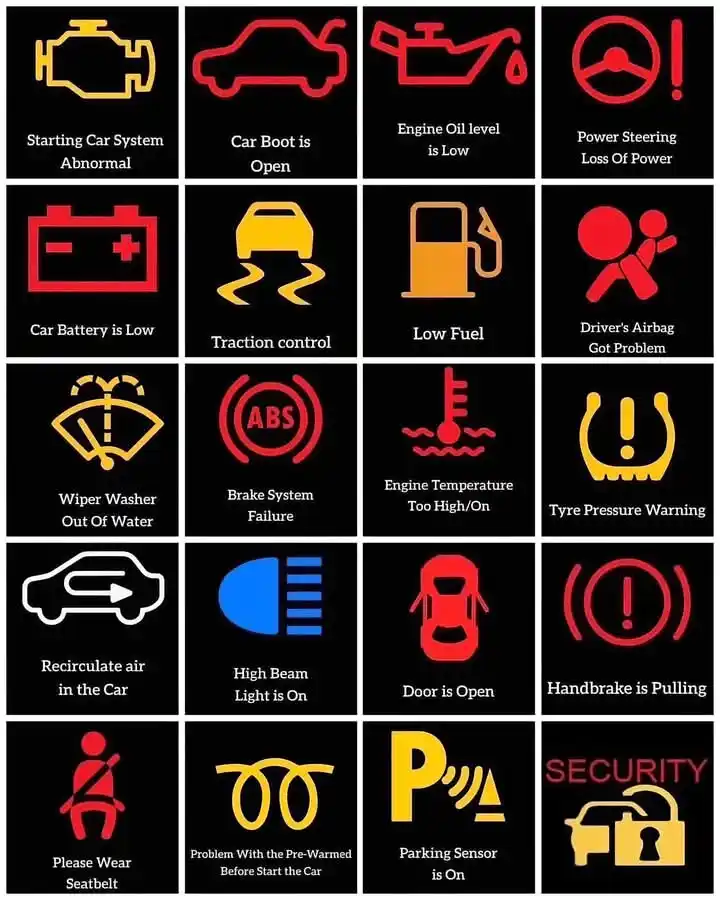

Car warning lights are crucial for alerting drivers about potential issues with their vehicle. Here’s a breakdown of some common ones: 1. Check Engine Light: Indicates an issue with the engine or emissions system. It could be minor or severe, so it’s best to get it checked. 2. Oil Pressure Light: Warns of low oil pressure, which can lead to engine damage if not addressed quickly. 3. Battery Light: Signals a problem with the car’s charging system, possibly due to a faulty alternator or battery. 4. Brake System Warning: Shows issues with the braking system, from low brake fluid to possible brake failure. 5. Tire Pressure Light: Alerts you of low tire pressure, which can affect fuel efficiency and tire wear. Always check your vehicle’s manual to understand what each light means for your specific model. #CarMaintenance #SafetyFirst #VehicleCare #DriveSmart #CarIssues #WarningLights Mechanics Manual

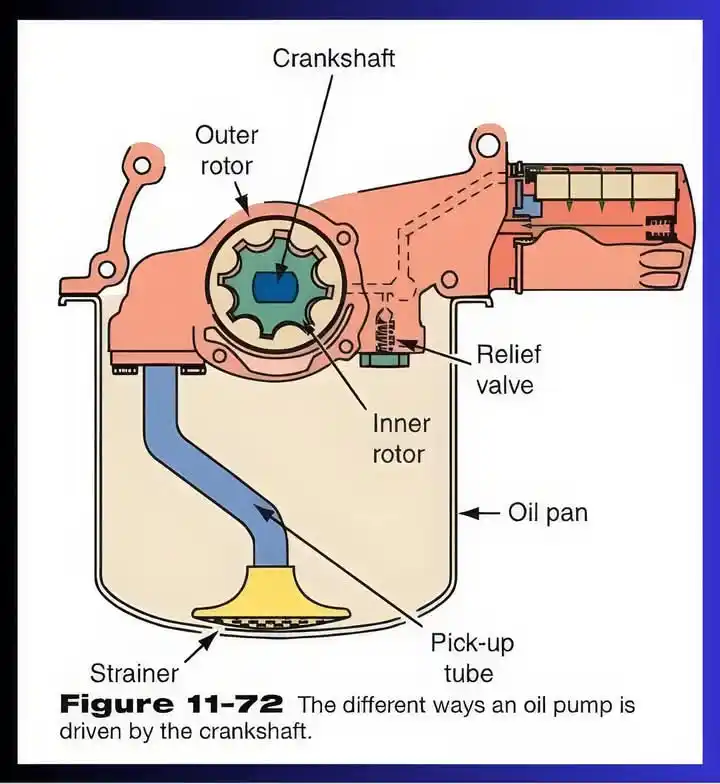

Oil pumps are the unsung heroes of your engine’s lubrication system. Here’s a quick look at their essential function, how they work, and key tips to keep them running smoothly. Role of Oil Pumps Oil pumps circulate oil throughout the engine to cool, clean, and lubricate moving parts. They are typically driven by the crankshaft, creating suction to move oil from the pan through a filter and into the engine’s passages. How Oil Pumps Work Oil pumps don’t create pressure—they only move oil. Oil pressure is generated as the oil faces resistance in the engine’s passages. Smaller passages result in higher oil pressure, while larger ones lower it. Factors Influencing Oil Pressure • Bearing Clearances: Wider clearances reduce pressure but increase the oil flow. • Oil Viscosity: Thicker oil creates more resistance, leading to higher pressure. • Temperature: Hotter oil becomes thinner, lowering pressure. Maintenance Tips • Regular oil changes prevent blockages. • Monitor oil pressure to detect issues early. • Check for leaks to avoid oil loss. • Use the manufacturer-recommended oil. By following these tips, you can extend your engine’s lifespan and avoid costly repairs. #OilPumps #EngineHealth #Lubrication #VehicleMaintenance #CarCare #AutoRepair