Welding Fabrication World

February 15, 2025 at 05:34 AM

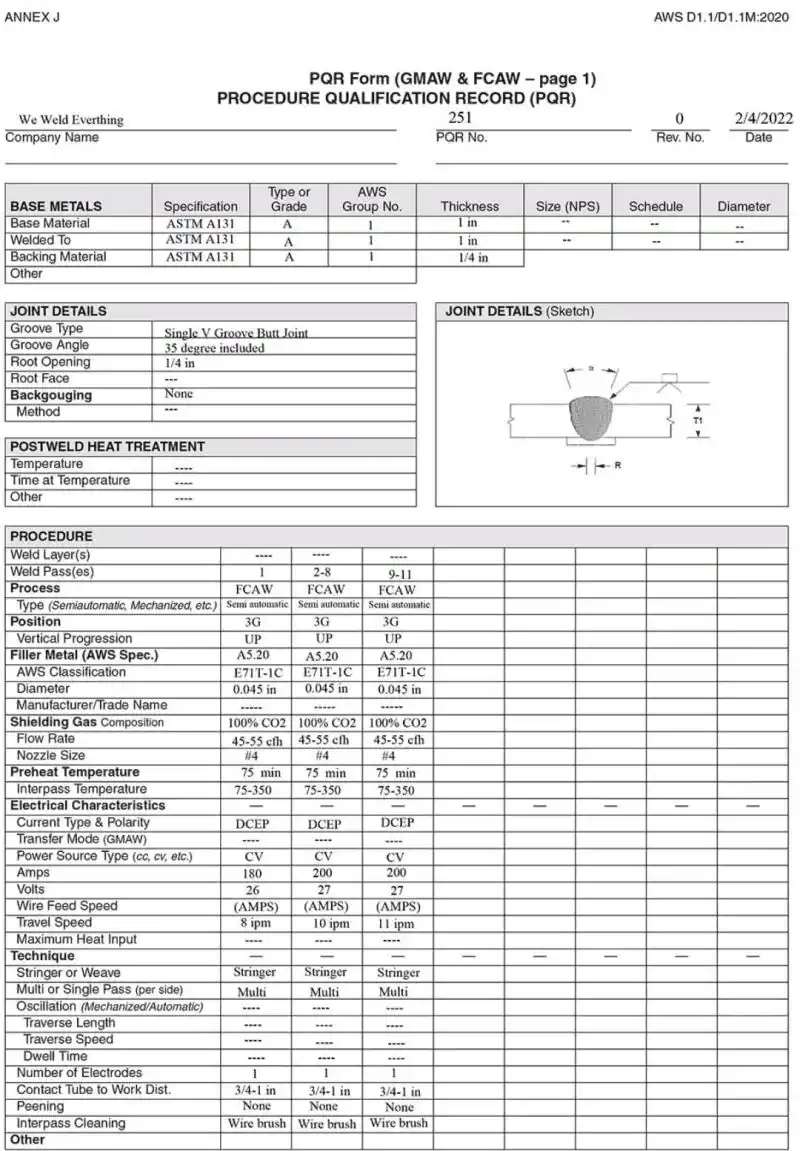

A PQR (Procedure Qualification Record) in welding is a formal document that records all the details and test results of a weld procedure that has been tested to ensure it meets the applicable standards and specifications. It serves as evidence that the welding procedure is capable of producing sound welds.

Key Elements of a PQR:

1. Welding Process: The specific process used (e.g., SMAW, GTAW, GMAW, etc.).

2. Base Materials: Details about the materials being welded, including their grade and type.

3. Filler Metal: Type, grade, and classification of the filler material.

4. Joint Design: Specifications of the joint configuration.

5. Welding Position: Position of welding (e.g., flat, vertical, overhead).

6. Preheat and Post-heat Requirements: Temperature requirements before and after welding.

7. Electrical Parameters: Voltage, amperage, and travel speed used.

8. Shielding Gas: Type and flow rate of the gas (if applicable).

9. Weld Tests: Results of destructive and non-destructive testing (e.g., tensile tests, bend tests, radiography).

10. Inspection Results: Visual inspections and other assessments of weld quality.

Purpose of a PQR:

To qualify a Welding Procedure Specification (WPS).

To ensure compliance with applicable welding codes and standards (e.g., ASME, AWS, ISO).

To verify the repeatability and reliability of the welding procedure.

Differences Between PQR and WPS:

PQR: A record of the actual weld procedure test and its results. It cannot be changed once recorded.

WPS: A document that provides instructions to the welder on how to perform the welding. It is derived from the PQR and can be modified as needed within the qualified range.

👍

1