Welding Fabrication World

146 subscribers

About Welding Fabrication World

Our Website WeldFabWorld.com Facebook page : https://www.facebook.com/WeldFabWorld X Account : https://x.com/Weldfabworld?t=5QjAsGlv0QykebKk3OGdRQ&s=09 Telegram : https://t.me/weldfabworld

Similar Channels

Swipe to see more

Posts

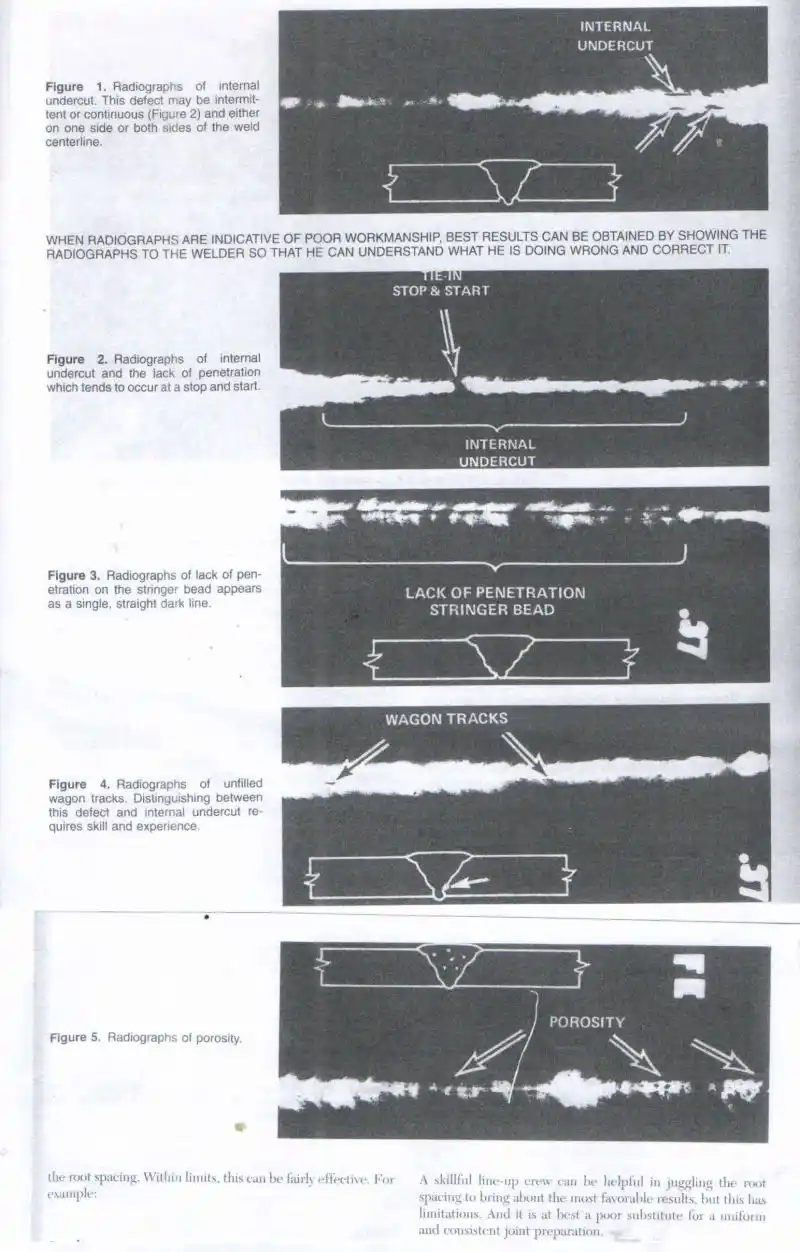

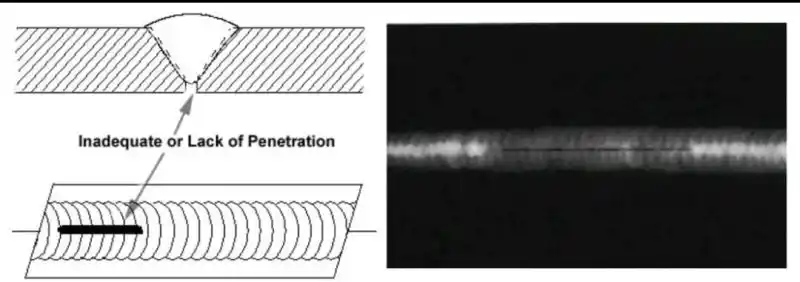

Here’s a concise description of the five pipeline welding defects illustrated in the radiographs: Internal Undercut (Figure 1): This defect appears as grooves along the weld edges, potentially intermittent or continuous. It weakens the joint by reducing the effective weld area. Stop and Start Undercut with Lack of Penetration (Figure 2): Occurs at tie-ins where welds start or stop. Internal undercut and incomplete fusion or penetration result in weak joints prone to failure under stress. Lack of Penetration on Stringer Bead (Figure 3): Displays as a single, dark line indicating insufficient weld fusion at the root. This creates a weak spot that compromises the integrity of the pipeline. Wagon Tracks (Figure 4): These are unfilled grooves along the weld edges, resembling parallel tracks. Skilled interpretation is required to distinguish them from internal undercut. Porosity (Figure 5): Characterized by small gas pockets within the weld, appearing as scattered dark spots. These reduce weld strength and durability. Each defect compromises the structural reliability of the weld and highlights the importance of proper technique and joint preparation. Pipeline Rules of Thumb E.W. McAllister 2002 GPP #undercut #porosity #wagontracks #penetration

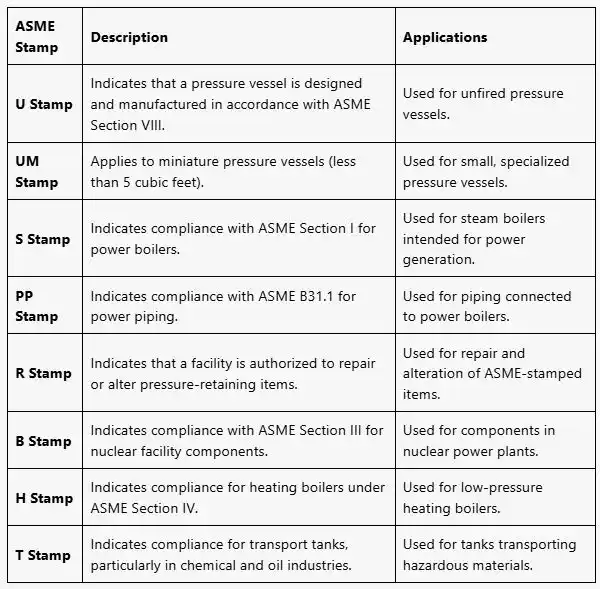

A Very Important Topic: 𝐀𝐒𝐌𝐄 𝐒𝐭𝐚𝐦𝐩𝐬 ASME (American Society of Mechanical Engineers) stamps indicate compliance with specific standards related to pressure vessels, boilers, and piping. Here's a breakdown of the key ASME stamps and their differences: 𝐒𝐮𝐦𝐦𝐚𝐫𝐲 𝐨𝐟 𝐃𝐢𝐟𝐟𝐞𝐫𝐞𝐧𝐜𝐞𝐬 𝑷𝒖𝒓𝒑𝒐𝒔𝒆: Each stamp corresponds to different ASME sections and standards, indicating the type of equipment and its intended use. 𝑺𝒄𝒐𝒑𝒆: The U and S stamps apply to general pressure vessels and power boilers, while others like UM and T focus on specific applications or sizes. 𝑹𝒆𝒈𝒖𝒍𝒂𝒕𝒐𝒓𝒚 𝑪𝒐𝒎𝒑𝒍𝒊𝒂𝒏𝒄𝒆: Each stamp signifies adherence to safety and quality regulations relevant to its category, ensuring the equipment meets industry standards. Understanding these differences is crucial for manufacturers and operators to ensure compliance with safety regulations and standards in their respective industries. Abdulkader Alshereef #Quality #ASME #Mechanical #PBV #Static #PressureVessels #Codes #Standards #QualityControl #Inspection #Boilers #Piping #Projects #Refinery #Facility

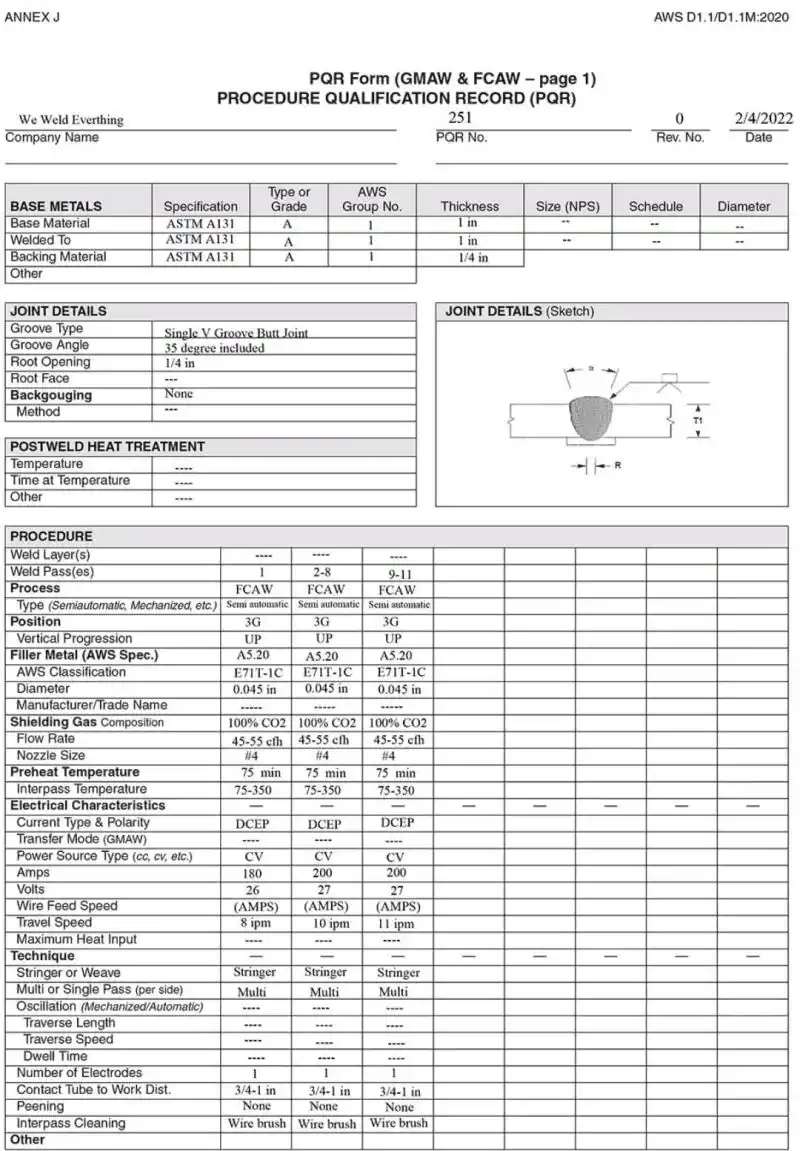

A PQR (Procedure Qualification Record) in welding is a formal document that records all the details and test results of a weld procedure that has been tested to ensure it meets the applicable standards and specifications. It serves as evidence that the welding procedure is capable of producing sound welds. Key Elements of a PQR: 1. Welding Process: The specific process used (e.g., SMAW, GTAW, GMAW, etc.). 2. Base Materials: Details about the materials being welded, including their grade and type. 3. Filler Metal: Type, grade, and classification of the filler material. 4. Joint Design: Specifications of the joint configuration. 5. Welding Position: Position of welding (e.g., flat, vertical, overhead). 6. Preheat and Post-heat Requirements: Temperature requirements before and after welding. 7. Electrical Parameters: Voltage, amperage, and travel speed used. 8. Shielding Gas: Type and flow rate of the gas (if applicable). 9. Weld Tests: Results of destructive and non-destructive testing (e.g., tensile tests, bend tests, radiography). 10. Inspection Results: Visual inspections and other assessments of weld quality. Purpose of a PQR: To qualify a Welding Procedure Specification (WPS). To ensure compliance with applicable welding codes and standards (e.g., ASME, AWS, ISO). To verify the repeatability and reliability of the welding procedure. Differences Between PQR and WPS: PQR: A record of the actual weld procedure test and its results. It cannot be changed once recorded. WPS: A document that provides instructions to the welder on how to perform the welding. It is derived from the PQR and can be modified as needed within the qualified range.

Incomplete Penetration in Welding: Causes and Prevention Incomplete penetration occurs when the weld metal does not fully fuse with the base metal or root of the joint, creating a weak weld that can fail under stress. This defect is critical in structural and pressure-containing applications, where full fusion is essential for strength and durability. Common Causes of Incomplete Penetration ⚠️ Low Welding Current – Insufficient heat prevents full fusion. ⚠️ Improper Joint Preparation – Inadequate root gap or bevel angle restricts penetration. ⚠️ Fast Travel Speed – Moving too quickly can prevent full fusion. ⚠️ Incorrect Electrode Size or Type – Using the wrong electrode can lead to poor penetration. ⚠️ Improper Torch or Electrode Angle – Poor positioning affects heat distribution. How to Prevent Incomplete Penetration ✔️ Use the correct welding current and voltage for adequate heat input. ✔️ Ensure proper joint preparation with the right root gap and bevel angle. ✔️ Adjust travel speed to allow full fusion without excessive buildup. ✔️ Select the appropriate electrode or filler metal for the material and thickness. ✔️ Maintain the correct welding technique and electrode angle. Ensuring complete penetration is key to producing strong, defect-free welds that can withstand stress and pressure.

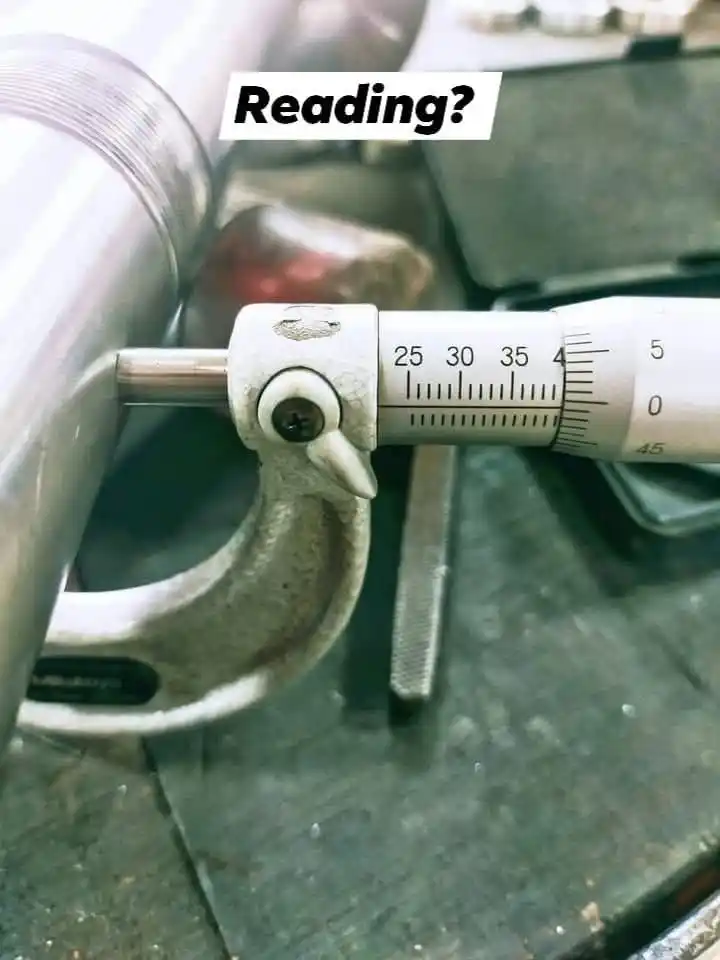

Reading? #engagement #engineering #QC #knowledgeispower #mechanical