Welding Fabrication World

February 15, 2025 at 02:31 PM

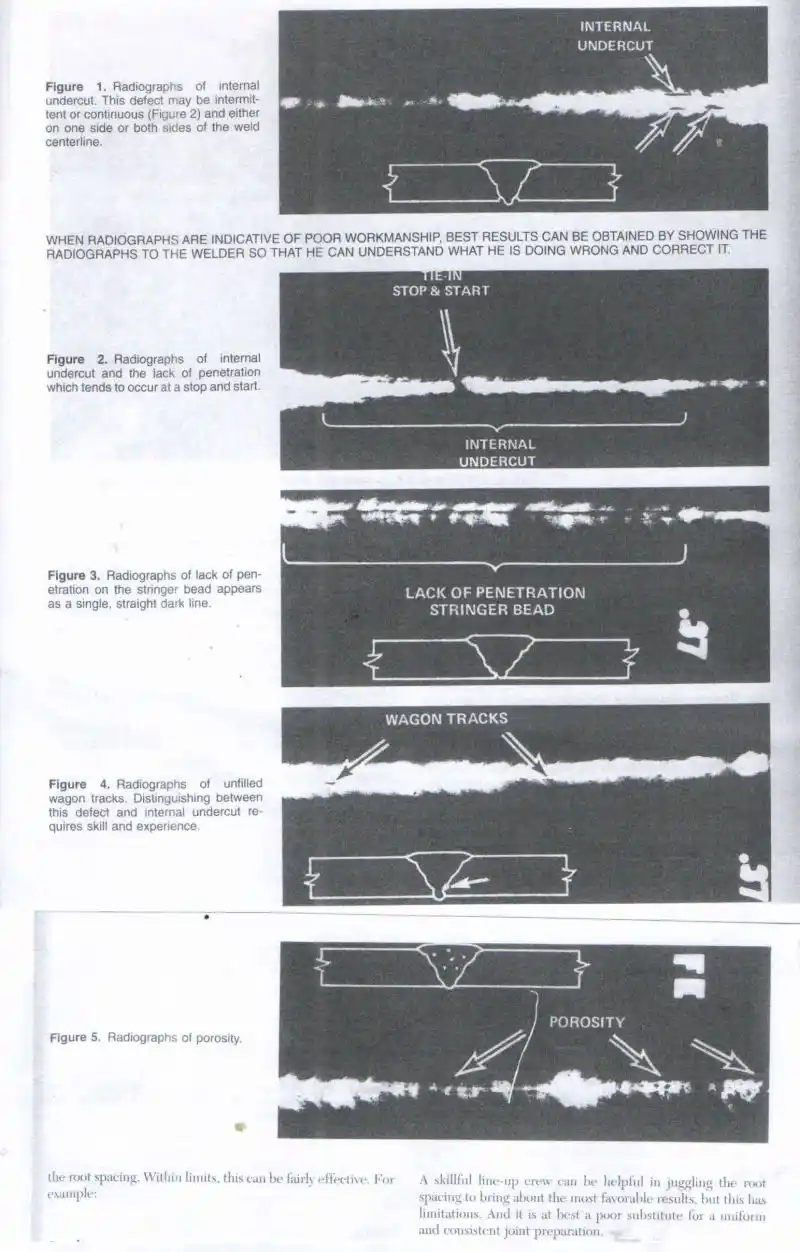

Here’s a concise description of the five pipeline welding defects illustrated in the radiographs:

Internal Undercut (Figure 1): This defect appears as grooves along the weld edges, potentially intermittent or continuous. It weakens the joint by reducing the effective weld area.

Stop and Start Undercut with Lack of Penetration (Figure 2): Occurs at tie-ins where welds start or stop. Internal undercut and incomplete fusion or penetration result in weak joints prone to failure under stress.

Lack of Penetration on Stringer Bead (Figure 3): Displays as a single, dark line indicating insufficient weld fusion at the root. This creates a weak spot that compromises the integrity of the pipeline.

Wagon Tracks (Figure 4): These are unfilled grooves along the weld edges, resembling parallel tracks. Skilled interpretation is required to distinguish them from internal undercut.

Porosity (Figure 5): Characterized by small gas pockets within the weld, appearing as scattered dark spots. These reduce weld strength and durability.

Each defect compromises the structural reliability of the weld and highlights the importance of proper technique and joint preparation.

Pipeline Rules of Thumb E.W. McAllister 2002 GPP

#undercut #porosity #wagontracks #penetration