Welding Fabrication World

February 16, 2025 at 02:53 PM

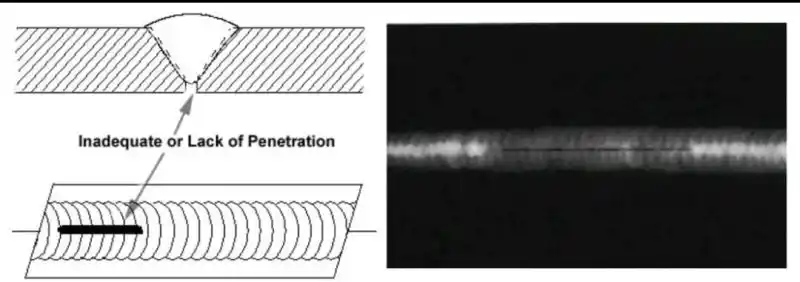

Incomplete Penetration in Welding: Causes and Prevention

Incomplete penetration occurs when the weld metal does not fully fuse with the base metal or root of the joint, creating a weak weld that can fail under stress. This defect is critical in structural and pressure-containing applications, where full fusion is essential for strength and durability.

Common Causes of Incomplete Penetration

⚠️ Low Welding Current – Insufficient heat prevents full fusion.

⚠️ Improper Joint Preparation – Inadequate root gap or bevel angle restricts penetration.

⚠️ Fast Travel Speed – Moving too quickly can prevent full fusion.

⚠️ Incorrect Electrode Size or Type – Using the wrong electrode can lead to poor penetration.

⚠️ Improper Torch or Electrode Angle – Poor positioning affects heat distribution.

How to Prevent Incomplete Penetration

✔️ Use the correct welding current and voltage for adequate heat input.

✔️ Ensure proper joint preparation with the right root gap and bevel angle.

✔️ Adjust travel speed to allow full fusion without excessive buildup.

✔️ Select the appropriate electrode or filler metal for the material and thickness.

✔️ Maintain the correct welding technique and electrode angle.

Ensuring complete penetration is key to producing strong, defect-free welds that can withstand stress and pressure.