Piping Engineering World

June 16, 2025 at 06:41 PM

#isometric drawings of pipes

Isometric piping diagrams are isometric representation of a single pipeline in the factory. It's the most important output of pipeline engineering department. Pipe manufacturing work depends on isometric drawings.

The isometric diagram of pipes consists of three sections. The main section consists of isometric representation of the pipeline path in 3D space, and includes the following information:

1. The line number.

2. The direction of the flow

3. Poster signs and props.

4. Site of pipe components.

5. Welding sites.

The section to the left or right of the drawing includes a material list section for the portion of the line that appears in the isometric drawing. This section includes the following information for all components:

1. Describing the ingredients.

2. The ingredient code.

3. Nominal size.

4. Quantity.

5. Whether material for manufacturing shop or field work.

6. The number of pieces.

The title bar section at the bottom includes the following information:

1. Project details such as client name, engineering office name, project name, project number, project processor license, etc.

2. Pipeline details such as line number, line size, isolation, tracing, liquid code, operating and design pressure and temperature, pressure testing method such as hydraulic or aeronautical test, test pressure, pipe material category, inch diameter, etc.

Accounts:

Inch Meter = Length of pipes in meter x Size of pipes in inch

Inch Dia = size of pipes in inch x number of connections

Isometric Diagram Checklist:

The isometric diagram should be checked according to the project's isometric diagram checklist. This list includes general points as well as project-specific points.

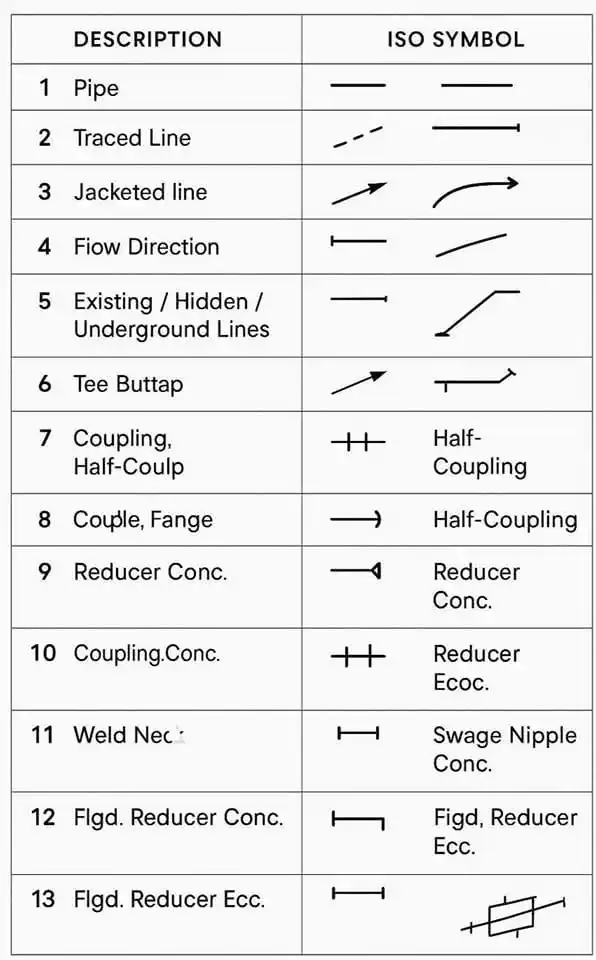

Symbols of Isometric Graphics

Description: Link of codes

Project-specific instructions for testing isometers: Each project has its own requirements. These requirements should be reflected in isometric diagrams. Some of these requirements may relate to:

1. Pressure Safety Valves

Screw Supply Range (Input/Output)

Bolts and bolts in the line, inlet or exit.

2. Fire fighting lines

Pipe cutting requirements.

Types of edges (flat edge or high edge).

3. Ventilation and practical drainage

Ventilation and drainage requirements for hydraulic testing.

Direct distance requirements for flow meters.

4. Insulation of pipes

Isolation fish and its range.

5. Selection of valves / alignment

6. Requirements of jack score rim.

7. Identification of the Pros.

8. The requirements of connections / lovers.

9. Dimensions of galvanized pipe cutting.

10. Signs of the rooster crowing.

11. Notes of mounting props.

12. Channeling the rim of the Orivice.

13. Sequence of delivery in PID layout

14. Edges/fills and bolts at the end of iso sheet.

15. Philosophy of disconnection of paper.

---

The professional post:

🔧 Everything you need to know about pipe isometric drawings! 🛠️

Isometric drawings are an essential component in the design and execution of piping in industrial projects. In these graphs, you can find everything about the pipeline, from line number to welding locations and props. These drawings are the document on which the piping department relies on to carry out the work accurately and professionally.

💡 What the isometric diagrams include:

1. Basic information such as line number, flow direction, and pipe supports.

2. Detailed information such as details of materials, sizes and quantities.

3. Tests and methods of testing pressure like hydraulic or aeronautical.

4. Special project requirements such as safety valves, isolation requirements and isometric graph codes.

📊 Special project modifications include:

Safety valves

Fire fighting lines

The requirements of isolation

Steering the edges

Requirements of Rolled Edges