Piping Engineering World

June 19, 2025 at 05:50 PM

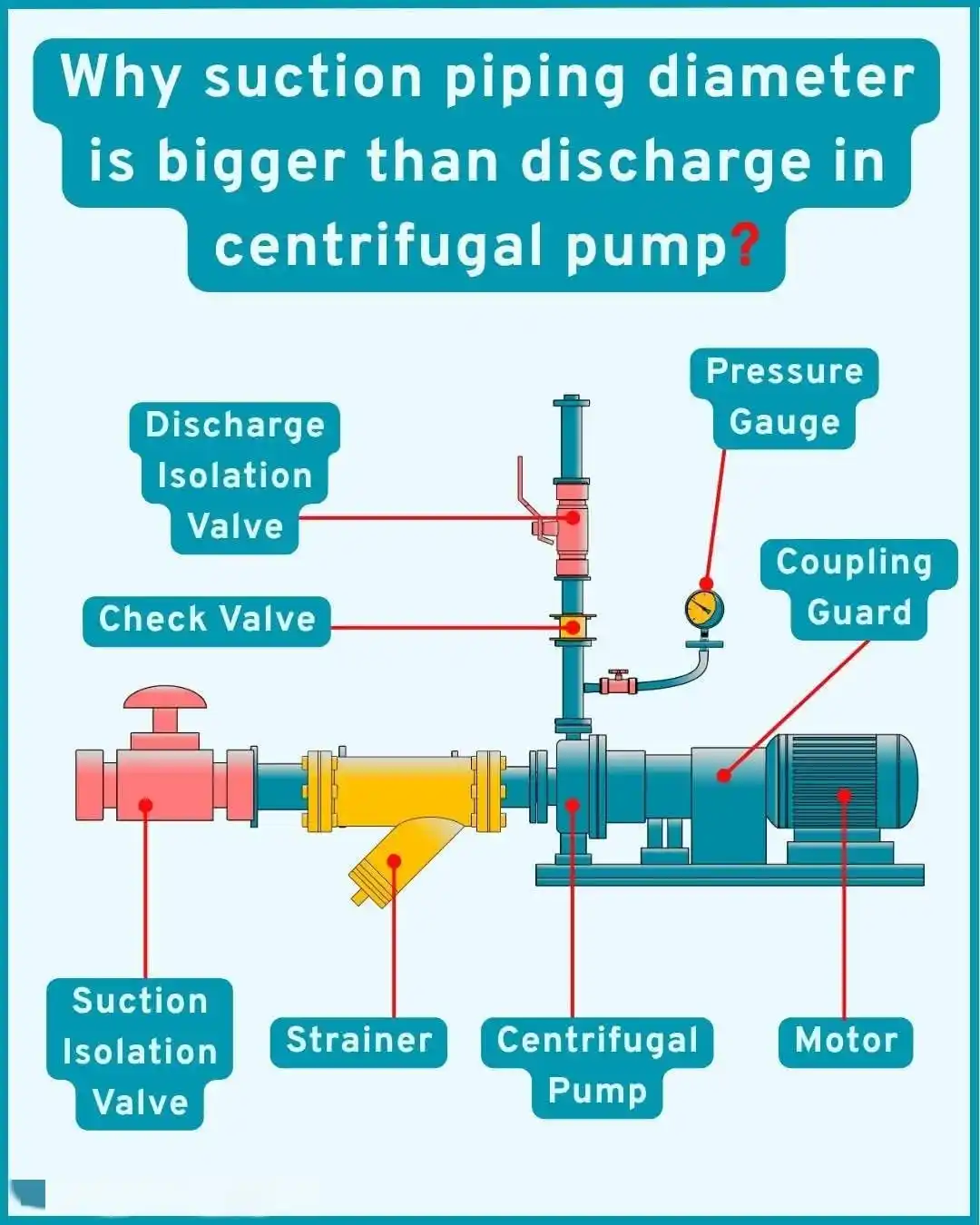

Why suction piping diameter is bigger than discharge in centrifugal pump❓

👉 In the world of fluid dynamics and mechanical engineering, centrifugal pumps play a crucial role in transporting liquids from one place to another. A key aspect of their design and operation is the sizing of the suction and discharge piping. Typically, the suction piping of a centrifugal pump is larger in diameter than the discharge piping. This design choice is not arbitrary but is based on several important principles of physics and engineering. Let's delve into why suction piping diameter is often bigger than the discharge piping in centrifugal pumps.

👉 Understanding Centrifugal Pumps

First, it's essential to understand how a centrifugal pump works. A centrifugal pump uses an impeller to add velocity to a liquid, which is then converted into flow. The liquid enters the pump through the suction inlet, where it is accelerated by the impeller and then discharged through the outlet. The efficiency and effectiveness of this process depend significantly on the design and sizing of the pump and its associated piping.

👉 The Role of Suction Piping

The suction piping is responsible for delivering the liquid to the pump. The primary goal here is to ensure that the liquid reaches the pump with minimal resistance and without causing cavitation, which is the formation of vapor cavities in a liquid due to low pressure. Cavitation can cause significant damage to the pump and reduce its efficiency.

👉 Why Larger Suction Piping?

1️⃣ Reducing Friction Losses: A larger diameter pipe results in lower fluid velocity, which in turn reduces friction losses. Lower friction losses mean that the liquid can flow more easily into the pump, reducing the energy required to move the liquid and minimizing the risk of cavitation.

2️⃣ Minimizing Pressure Drop: As liquid flows through a pipe, there is a natural drop in pressure due to friction and other factors. A larger diameter pipe helps to minimize this pressure drop, ensuring that the liquid reaches the pump at a higher pressure. This is crucial for maintaining the Net Positive Suction Head (NPSH), which is the difference between the pressure at the suction inlet and the vapor pressure of the liquid. Adequate NPSH is essential for preventing cavitation.

3️⃣ Enhancing Pump Efficiency: By reducing friction losses and minimizing pressure drop, a larger suction piping diameter helps to enhance the overall efficiency of the pump. This means that the pump can operate more effectively, with less energy consumption and reduced wear and tear.

4️⃣ Handling Viscous Liquids: When dealing with viscous liquids, which have a higher resistance to flow, a larger suction piping diameter becomes even more important. The increased diameter helps to accommodate the higher resistance and ensures smooth flow into the pump.

👉 The Role of Discharge Piping

The discharge piping, on the other hand, is responsible for transporting the liquid from the pump to its destination. The primary goal here is to deliver the liquid at the desired flow rate and pressure. A smaller diameter pipe is often used for discharge piping because it helps to maintain higher fluid velocity and pressure, which are essential for effective transportation and distribution of the liquid.